We CAN learn from our mistakes…providing our project management system delivers the goods!

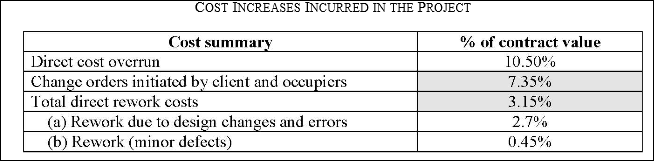

Through their research “Forensic Project Management: An Exploratory Examination of the Causal Behavior of Design-Induced Rework,” Peter E. D. Love, David J. Edwards and Zahir Irani found, on average, that rework contributed 52% of a project’s total cost overrun, and concluded that “having to unnecessarily repeat activities or processes that were incorrectly implemented the first time within a project can adversely affect the profitability, performance, and reputation of those organization(s) involved; as well as a project’s organizational and social fabric.”

According to Love, Edwards and Irani,

- The determination as to why projects fail to meet planned schedule, cost, and quality parameters is a leitmotiv within the construction, engineering, and project management literature.

- Design-induced rework has been reported to contribute more than 70% of the total amount of rework experienced in construction and engineering projects.

- The mitigation of design-induced errors would significantly reduce the amount of rework that architectural and engineering firms experience. This would bring with it greater profitability for such firms and improved project performance parameters (schedule, cost, and quality).

Also, according to work by James M. Lyneis and David N. Ford as well as by Kim van Oorschot, the failure to meet project targets is caused by an asymmetric uncertainty:

On the one hand, the project workload is underestimated (new unexpected tasks are discovered during project execution, mistakes require unexpected rework, customers desire unexpected changes of the initial design).

On the other hand, project workforce is overestimated (subcontractors and team members are still tied up on other projects that are delayed, it takes time to assemble a team and to train newcomers).

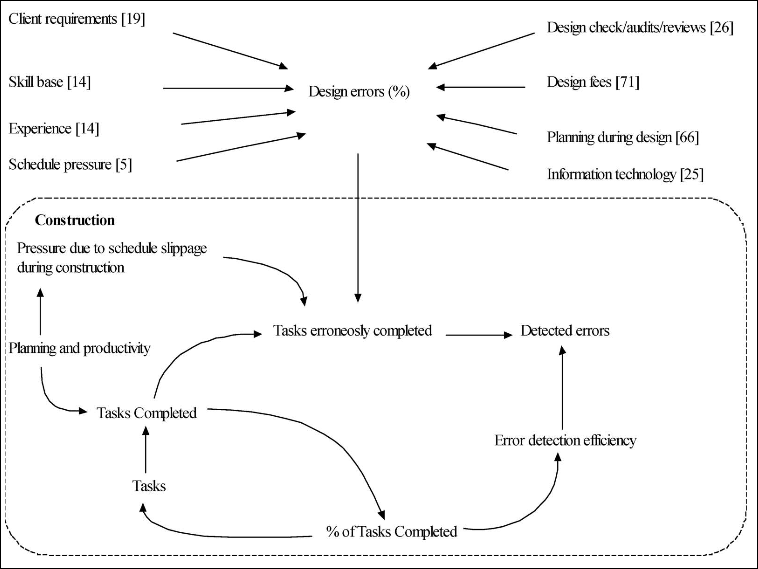

Influencing factors include the following:

- Project features

- Interpretation of project task remaining and project tasks completed

- Management’s drive/targets for earned value billing and revenue recognition

- Rework cycle

- Tasks volume and complexity

- When project tasks are performed, mistakes are made that require rework

- This rework is usually undiscovered at first, which leads to a misinterpretation of actual progress exasperating project features

- Once discovered, the total remaining work increases

- Construction projects can take as much as two and a half cycles to rectify rework activities

- Project control

- Project managers need to deliver project within constraints in terms of time, budget and quality

- Both goal seeking (hiring additional staff, working overtime, or working faster) and goal adjustment pose significant pressure on overall project constraints and contract terms

- Ripple and knock-on effect

- Whereas the ripple effects are the primary side-effects of well-intentioned project controls

- Whereas the knock-on effect is the longer a mistake remains undetected, additional mistakes are created downstream as subsequent tasks inherit the original mistakes

- Stakeholder–Project Partner collaboration

- Frequently, communication between designers and the end-user of the facility is indirect, and as such, tends to be filtered by organizational politics and power struggles

- 25% of rework costs are related to customer change orders

Case Study

Love et al present a case study:

The project consisted of two residential blocks of six-storeys each, which combined comprised 43 units. An underground car parking, a landscaped podium, and a swimming pool were among the facilities incorporated into this development. The project had a contract value of AUS $10.96 million, a contract period of 43 weeks, and was procured under a traditional lump arrangement. A 5-week extension time was granted. The project was issued with a certificate of practical completion 8 weeks ahead of the rescheduled completion date. While the project was delivered ahead of time, cost overruns were experienced due to change orders and rework.

The post-closed out research undertaken by Love found, on average, that rework contributed 52% of a project’s total cost overrun. No single cause for a design error could be identified from the analysis, and in many instances, the events that did occur were interconnected with one another.

Contributing Factors

- Collaboration:

The lack of design coordination, particularly between the architect and structural engineer during the design process, meant that both consultants lost sight of their respective roles in the project, and instead, concentrated on their own objectives and goals. The architectural and structural and drawings did not correspond with one another and contained an excess amount of errors, which were only detected on-site by the contractor.The non-interaction between key project participants resulted in the contractor’s project manager making the following comment:

You wouldn’t believe that they were working on the same project. The architectural drawings were incomplete, and the pitch of the roof was too steep, which meant that the building exceeded the height stipulated by Brisbane City Council.

- Bottlenecks:

Artificial bottlenecks in the flow of information contributed to less attention being given to coordination by the client’s project manager. Even more surprising was that the RFIs were not immediately forwarded to the architect and engineer, which resulted in periods of inactivity being experienced by the contractor.

Report Conclusions

If firms do not begin to reexamine their work practices, then there is a danger that errors become a norm and adversely impact on their overall profitability and the performance of the projects that they are involved with.

If firms are to be competitive in today’s environment, they should pay increasing attention to effectively managing their human resources, implementing quality management practices along with post-close-out Forensic Project Management with a vision of the future.

Think seriously about contacting Spitfire Management, LLC, if your current Project Management/Project Cost Accounting solution lacks the essential audit trails to perform Forensic Project Management.

Learn from your mistakes—learn to deliver on-time, on-budget and to maximize profit.

Tweet